18 November 2022

Categories: Knowledge Tags: bourdon tube gauge gauge pressure pressure gaugesDuring the industrial revolution when manufacturing switched from hand production to machines, water and steam engines became the main means of power generation within manufacturing. During the early days, there were numerous casualties and safety hazards associated with steam and pressure build-up. To solve the problem of managing the build-up of pressure, Eugène Bourdon invented the Bourdon Pressure Gauge in 1840.

What is a Bourdon Tube Pressure Gauge?

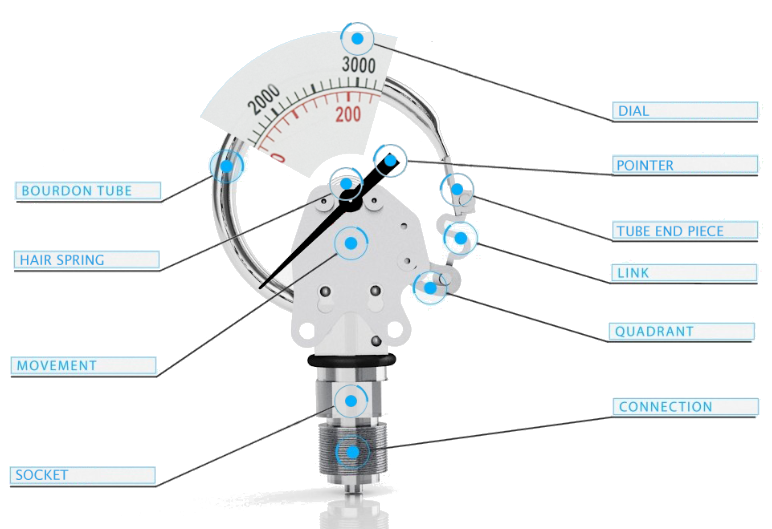

The principle of a Bourdon Tube Pressure Gauge is the C-shape or Coil shaped (Bourdon Tube). This is a radially formed hollow tube which, when media is forced within it, straightens up and moves a pointer which displays the pressure being generated. The C-shaped tube is generally bent at an angle of 270° and has a closed-end and an open-end that connects directly with the process media. For higher pressures, a coil-shaped tube is generally used.

The pointer movement is generated mechanically by the pressure within the Bourdon Tube and does not require any electricity to power it. The only other mechanical parts are the linkage at the end of the tube which can be adjusted when calibrating, a quadrant toothed segment that attaches to the movement, a gear, and a hairspring which is attached to the pointer.

Units of Pressure

The dial positioned behind the pointer displays the units appropriate to the minimum and maximum pressure associated with the specific gauge. These pressure measurements on the dial normally display the following units of pressure:

At sea level, the bar unit range is 1 bar. This unit of measurement is used widely in Europe.

The unit of measurement where 1 Lb of force is applied to 1 inch² of area. This unit of pressure is used widely in the United States/ United Kingdom.

1 Pa equals one Newton of pressure per square metre.

The pressure directed onto a 1mm cylinder of mercury. Also commonly known as millimetre of mercury (mmHG). Commonly used to measure vacuum (negative pressure).

The pressure exerted onto a one-inch cylinder of mercury and more commonly used in the United States/United Kingdom. Commonly used to measure vacuum (negative pressure).

The measure of 1 inch cylinder of water at gravity and 4°C.

Manufacturing Options

There are a number of factors when manufacturing a Bourdon Tube that affects the pressure being measured. The main features are:

When manufacturing a high-pressure Bourdon Tube the thickness of the wall will need to be thicker. The temperature also affects the tube as a low temperature will make it more rigid and a high temperature will make it more pliable. The materials used to manufacture the tube are typically phosphor bronze or stainless steel.

Certifications and Standards for Bourdon Tube Pressure Gauges

All Budenberg Bourdon Tube Pressure Gauges conform to EN 837-1 and P.E.P safety standards. All units also conform to IP as defined in EN 60 529 environmental standards and further certifications include BS EN 10204 3.1B Material and Point by Point Certificate.

Types of Bourdon Tube Pressure Gauges

The most common types of Pressure Gauges that use the Bourdon Tube principle are gauges for measuring gauge pressure/vacuum and differential pressure.

For safety-critical applications such as high pressure gas over 25 bar or steam, a specially designed blow-out back is used so that anyone standing in front of the pressure gauge is protected.

To create a differential gauge, two bourdon tubes are used to measure two pressure points on a single pipe system. Differential gauges are used to measure flow, filtration, levels of a liquid and differential pressure inflow.

Typical Examples of Bourdon Tube Pressure Gauges

Budenberg Gauge has been manufacturing Bourdon Tube Pressure Gauges for over 170 years and has a large range of gauges for every project. Here are just a few examples of what Budenberg can manufacture (Custom design options are also available):

Pressure Gauge with Safety Pattern Construction

(Bourdon Tube for ≤80 Bar)

(Bourdon Coil for ≥81 Bar)

Model: 966GP

Very High-Pressure Gauge with Safety Pattern Construction

(Bourdon Coil)

Model: 964GP/564GP

Rubber Capsule Grout Gauge

(Bourdon Tube)

Model: 202

Differential Pressure Gauge

(Bourdon Tube x2)

Model: 179

For further information regarding Bourdon Tubes Pressure Gauges, please contact our technical sales team..

Your details will not be shared with any organisation outside of Budenberg Gauge Co. Ltd. You may request to be removed from our database at any time.

To see our full privacy policy click here.

Budenberg Gauge Co Ltd is a premier manufacturer of instrumentation for a wide range of applications and markets. Quality and reliability have become the trademark of all Budenberg products and all our instruments are supplied with a standard warranty and carry a unique serial number for traceability purposes.