15 January 2021

Categories: Knowledge Tags: differential pressure gauge differential pressure inflow filtration level of a liquidEven if you have a vague awareness of differential pressure gauges, it can be easy to misunderstand or look past their usefulness and versatility. However, that's set to change thanks to this handy guide put together by the Budenberg team.

What is a differential pressure gauge?

What is a differential pressure gauge?

To put it simply, a differential pressure gauges is an object that acts as an essential visual indicator of the difference of pressure between two pressure points of one pipe system. Most commonly, differential pressure gauges are used within industrial process systems, such as those installed in chemical plants, petrochemical plants, Power plants and refineries.

Differential pressure gauges have many uses, including but not limited to liquid flow, liquid levels, and efficiency of filtration. You should be careful not to confuse differential pressure gauges with standard pressure gauges, as the latter measure the pressure at just a single point compared to two.

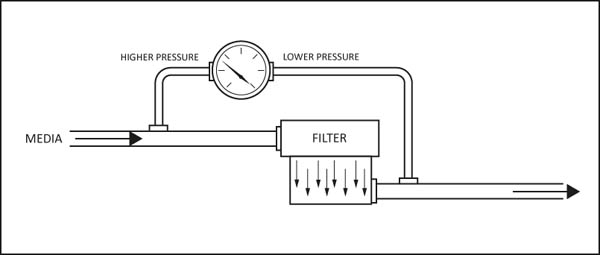

The filtration sector is where differential pressure gauges are predominantly used. Here, they play an important role to ensure that the pressure remains consistent throughout the filtration system. This is important because, as filters remove unwanted particles, bacteria, and other foreign objects, the filtration system can in time become clogged or broken.

This causes the pressure to drop throughout the filtration system, which reduces the efficiency of the filtration process. Thus, the use of differential pressure gauges at regular intervals ensures that filtration systems are kept at their required function levels, saving companies time, resources, and money.

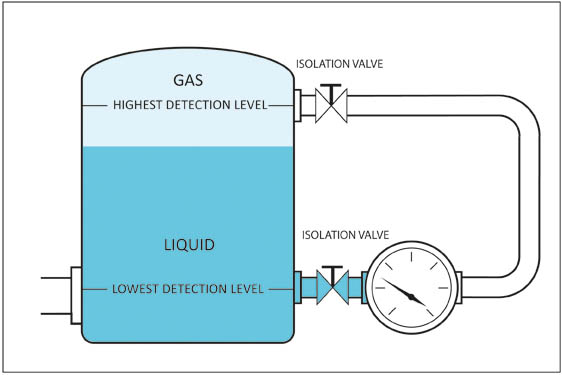

Another use of differential pressure gauges is the monitoring of the level of a liquid, such as those stored in sealed tanks. Thanks to the pressure from the gas blanket, it can be difficult to get an accurate reading using a standard pressure gauge alone.

Differential pressure gauges, on the other hand, are more effective at reading liquid levels within a tank because they read two different points simultaneously. Not only this, but differential pressure gauges specifically measure the difference in gas pressure compared to overall pressure, which allows users to translate the results into a reading of a true liquid level.

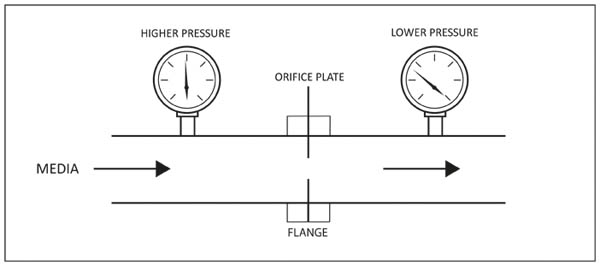

The flow of pressure inside a pipe is of equal importance. Again, differential pressure gauges are critical in determining such inflow of liquid within any pipe. In particular, differential pressure gauges measure the liquid inflow rates before and after a diameter-reducing item is inserted. The items that could be used to reduce the diameter of a pipe include orifice plates, flow nozzles, or venturis.

Thanks to the efficiency of two measurement points at once, differential pressure gauges remain the most effective method measuring liquid pressure inflow in a pipe.

There are many benefits to opting for a differential pressure measurement over a standard pressure measurement. Below, we've outlined just a few of the main advantages of differential pressure gauges being installed over any other product alternative.

Efficiency

As mentioned previously, differential pressure measurements are twice as effective at measuring the pressure, inflow, and liquid levels within a pipe, tank, or any other container. This is crucial for those industries and businesses where time is of the essence, such as water filtration companies that need to ensure their systems are working optimally at all times.

Simplicity

Another huge benefit of opting to install differential pressure gauges is the simplicity of the entire process. From initial installation to maintenance of the gauges to the measurement of the results as and when needed, differential pressure gauges are among the easiest tools to measure pressure and more with. All users need to do is tap into the storage system, such as a tank or pipe, and they're basically good to go.

Costs

Thanks to the very little installation needed when setting up differential pressure gauges, they are also a cheaper method of pressure tracking and measurement compared to alternatives. This is great news for smaller businesses that are attempting to establish quality practices without the extortionate costs that often accompany this. Differential pressure gauges are also cheaper to maintain, which results in smaller ongoing costs - again, another bonus for SMEs wanting to improve their business.

Invasiveness

Some pressure measuring products can impact the flow of the pressure thanks to their invasiveness. Those that choose to install differential pressure gauges need not worry about this issue, as differential pressure gauges are minimally invasive. This means that the flow of pressure, liquid and air is impacted less, resulting in a more consistent and reliable piece of kit.

Overall, differential pressure gauges are a necessity for those that work with pressure tanks or pipes, or else any businesses that need to frequently measure airflow and pressure levels. Here at Budenberg, we stock a range of exceptional differential pressure gauge products, including bourdon tubes, diaphragms and bellows

Bourdon tubes are a cheap, elastic form of pressure measurement, and can be used for the measurement of both gases and liquids. Despite being invented over a century ago in 1850, bourdon tubes are still regarded as one of the most reliable forms of pressure gauges available on the market today.

Diaphragm pressure gauges are most useful when it comes to the measurement of high-pressure containers. Predominantly, it measures the pressure of a liquid, but it can also effectively measure gas in many situations too. It's especially effective for measuring canisters of gas, or else measuring the strength of a vacuum within a pump.

Bellow type differential instruments are able to measure both low and high differential in conjunction with high static line pressure. Bellows gauges are known to be more sensitive than their counterparts, and so are better when it comes to measuring absolute pressure.

You can browse our full range of differential pressure gauges online or else get in touch with a friendly member of the Budenberg team today to learn more about how our products can help you out.

Your details will not be shared with any organisation outside of Budenberg Gauge Co. Ltd. You may request to be removed from our database at any time.

To see our full privacy policy click here.

Budenberg Gauge Co Ltd is a premier manufacturer of instrumentation for a wide range of applications and markets. Quality and reliability have become the trademark of all Budenberg products and all our instruments are supplied with a standard warranty and carry a unique serial number for traceability purposes.