1 November 2021

Categories: Knowledge Tags: bourdon tube gauge chemical seal diaphragm pressure gauge diaphragm seal pressure gauges schaffer diaphragm gauge A diaphragm pressure gauge or 'Chemical Seal' is an instrument normally used to measure the pressure of toxic, corrosive and fibrous media. If a standard pressure gauge were to be used it would be damaged, become clogged or would have a reduced life expectancy, if allowed to enter the sensitive mechanism and materials within the instrument.

A diaphragm pressure gauge or 'Chemical Seal' is an instrument normally used to measure the pressure of toxic, corrosive and fibrous media. If a standard pressure gauge were to be used it would be damaged, become clogged or would have a reduced life expectancy, if allowed to enter the sensitive mechanism and materials within the instrument.

The diaphragm can also be used to measure atmospheric pressure, the pressure within a gas canister or to measure a vacuum.

It is different to the standard bourdon pressure gauge in that it does not have a small inlet hole and does not allow the process media to enter the pressure gauge.

Uses for a Diaphragm Seal

Diaphragm seals are used in a wide range of industries including water treatment, oil and gas, petrochemical, chemical, food and beverages. The main usage for diaphragm seals includes:

Toxic Media: Typical fluids include alkalis and acids.

High Temperatures: Accurate measurement requirements of very hot process media.

Hygiene: To stop contamination of bacteria in pharmaceutical, food, brewing and dairy processes

Clogging: Processes such as slurry in water treatment plants require limited downtime and accurate readings.

Awkward Positions: A capillary measurement probe can be installed in tandem with a diaphragm seal making it easier to read the gauge, which would otherwise be in an unreadable position.

How it works

The diaphragm is clamped between two flanges and is circular with a flexible membrane that has two sides. The upper half of the membrane is filled with liquid compatible with the process medium and is calibrated to a predetermined amount. The lower half comes into contact with the process media which deflects the membrane upwards.

As the diaphragm deflects (moves up and down) from the process positive and/or negative pressure, the deflection is transmitted to the pressure gauge which displays the pressure on a dial.

There are many types of diaphragm and when selecting the most suitable one, style, environment, construction and maximum pressure have to be carefully considered.

Diaphragm Seals

The diaphragm seal units are commonly used in conjunction with a pressure gauge, but can also be used in conjunction with transmitters, transducers to protect these items from harsh environments and high pressure overloads. The typical method of measuring pressure with a diaphragm seal gauge is using a needle. Other methods can also be used such as measuring electrical resistance.

The electrical resistance strain gauge uses a strip of an electrical resistor which resists the flow of electricity. This is attached to a diaphragm which bends as the resistance increases. The more the strip bends, the more electrical resistance there is, this in turn, reduces the flow of current. When the electrical current is measured, the gauge can sense how much the diaphragm has moved and how much pressure is being created from the air outside. Chemical seal assemblies can also be used with transmitters, transducers and switches.

Hygienic Diaphragm Seal Gauge, Stainless Steel, Welded Seal

For dairy, brewing, pharmaceutical and food industries.

For dairy, brewing, pharmaceutical and food industries.

Schaffer Diaphragm, Stainless Steel Case, Screwed Connection

Schaffer diaphragm gauges are designed for use on slurries, viscous or corrosive fluids.

Schaffer diaphragm gauges are designed for use on slurries, viscous or corrosive fluids.

Schaffer Diaphragm, Stainless Steel Case, Flanged Connection

Schaffer diaphragm gauges

prevent issues that would normally attack or block standard bourdon tube gauges.

Schaffer diaphragm gauges

prevent issues that would normally attack or block standard bourdon tube gauges.

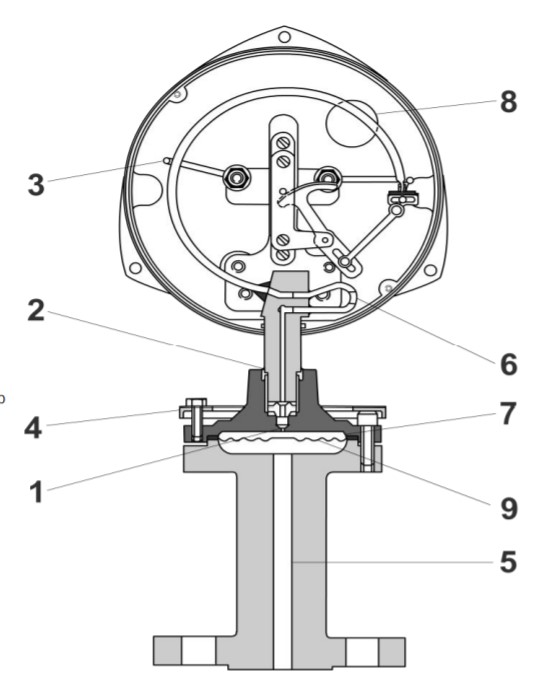

Example of an Ultra-Safe Budenberg Diaphragm Seal Gauge for Toxic Services

1. The small hole in the top flange ensures that if the filling liquid leaks off for any reason, the diaphragm seals over the hole and there is no escape of the process fluid (pressure medium)

2. The connection of the stainless steel gauge is welded to the upper flange to give an all-welded unit. This prevents the joint from being unscrewed accidentally. They can also be locked to the upper flange.

3. Overload stops on the tube allow the gauge to withstand 3x overpressure.

4. A plate with a sealed warning label deters the removal of screws.

5. Reduced bore on entry reduces the amount of toxic fluid released if the gauge has to be removed from the plant before the line is purged.

6. Capillary snubber is welded into a sealed system to reduce pulsations.

7. Diaphragm can be built to match upper-flange corrugations to allow the diaphragm to lock off against it in the event of an overpressure ensuring that the tube is not subjected to it.

8. Safety features such as 'blow out back' or discs, laminated safety glass and electrical contacts for use in hazardous areas can be fitted.

9. Gauges for toxic/hazardous processes are often fitted with tantalum diaphragms and an inert fluorine-based fill fluid.

Selecting a Diaphragm Seal

Due to the wide range of environments and difficult mediums that need to be measured, a flexible range of seal gauges and features is available.

Here are just some of the main considerations when selecting a Diaphragm Seal:

Typically, diaphragm seals are available as a clamped, welded or capsule construction.

The clamped construction is available with either a screwed or flange connection. Here, the seals are attached between the upper and lower housing allowing for easy removal and replacement.

Welded constructions are also available with a screwed connection. The diaphragm is welded to the upper housing which allows for the removal of the upper housing without loss of the fill fluid.

Budenberg manufactures a number of connection options that are renowned for the quality of their seal assemblies. Their 'Field Serviceable' chemical seals provide the option for removal and cleaning of wetted parts and also for the replacement of diaphragms which, in the long term will radically reduce operating costs: it is far more cost-effective to replace a diaphragm than a whole assembly whether connected to a gauge, transmitter or switch.

If you have any questions on selecting a Diaphragm Seal Gauge, please contact our technical sales team.

Your details will not be shared with any organisation outside of Budenberg Gauge Co. Ltd. You may request to be removed from our database at any time.

To see our full privacy policy click here.

Budenberg Gauge Co Ltd is a premier manufacturer of instrumentation for a wide range of applications and markets. Quality and reliability have become the trademark of all Budenberg products and all our instruments are supplied with a standard warranty and carry a unique serial number for traceability purposes.