15 December 2020

Categories: Knowledge Tags: double block and bleed double block valve monoblock valve single block and bleed valve single block valve

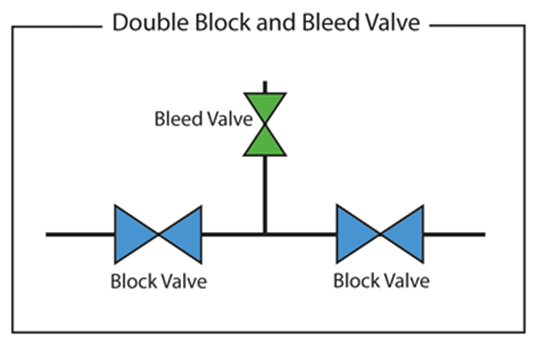

If you had never heard the words "Double Block and Bleed" your first thought may turn to a medical valve for blood or a martial arts move. The real meaning or use for a Double Block and Bleed valve (DBB) is in isolating the flow of media in a pipe using three valves.

The three valves are made up of two block valves and one bleed valve. Depending on the

process that the DBB is to be used in such as temperature and pressure, the assembly and materials will differ. If the valve is to be used in a noncritical

process then the use of a Single Block and Bleed (SBB) valve may be used.

Achieving Positive Isolation

Most Double Block and Bleed valves will be used when performing maintenance, repair or closing down of a section of piping. To achieve positive isolation both block valves are closed. When both block valves are closed the media flow will have stopped. The side which has been closed down can then be drained for safe access and any media trapped in-between the block valves can be drained using the bleed valve.

Applications of Double Block and Bleed

DBBs are primarily used in the oil and gas, petrochemical, storage, and transmission industries.

Benefits of Using a Double Block and Bleed Valve

By strategically incorporating DBBs into a process system you are increasing system integrity and reducing maintenance times. The key benefits of a DBB valve are:

How to choose a Double Block and Bleed Valve

Before choosing the type of valve that you require, it is recommended to consider the application, media, pressure, temperature, toxicity and environment in which it will operate.

As DBB valves are often used in highly critical processes, it is important to test them so that you know they satisfy the requirements.

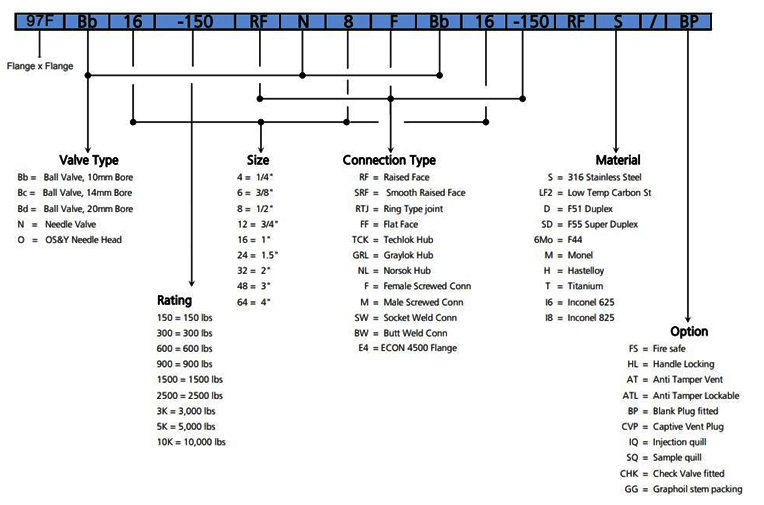

As an example, Budenberg Gauge Co Ltd have datasheets for all their DBB valves which details valve type, rating/pressure, size, connection type, material and options. To define a part number, all that is required is to use a chart to find the alphanumeric codes that will define the base unit and options. The below chart is a representation of their Model 97F Flange x Flange DBB:

A typical definition of a model 97F DBB might be:

If you are at all unsure which double block and bleed valve would fit your process needs, then please contact our technical team on +44 (0)161 777 7300.

View our range of Double Block and Bleed Valves or enquire through our

enquiry form.

Your details will not be shared with any organisation outside of Budenberg Gauge Co. Ltd. You may request to be removed from our database at any time.

To see our full privacy policy click here.

Budenberg Gauge Co Ltd is a premier manufacturer of instrumentation for a wide range of applications and markets. Quality and reliability have become the trademark of all Budenberg products and all our instruments are supplied with a standard warranty and carry a unique serial number for traceability purposes.