18 June 2021

Categories: Knowledge Tags: absolute pressure differential pressure gauge gauge pressure pressure gaugesDeciding on whether you require absolute or gauge reference pressure is extremely important in generating an accurate reading in your pressure applications. Selecting the wrong instrument could give you an error if measuring pressures at a lower range (1 bar for pneumatic instruments) or a substantial inaccurate reading if measuring pressure at a higher range (400 bar for hydraulics instruments).

To help you in determining which pressure reference you require, here are some guidelines which will hopefully help you identify the types of pressure measurement you will require:

| Pabs = Absolute Pressure |

| Patm= Atmospheric Pressure |

| Pg= Gauge Pressure |

| DP or ∆P = Differential Pressure |

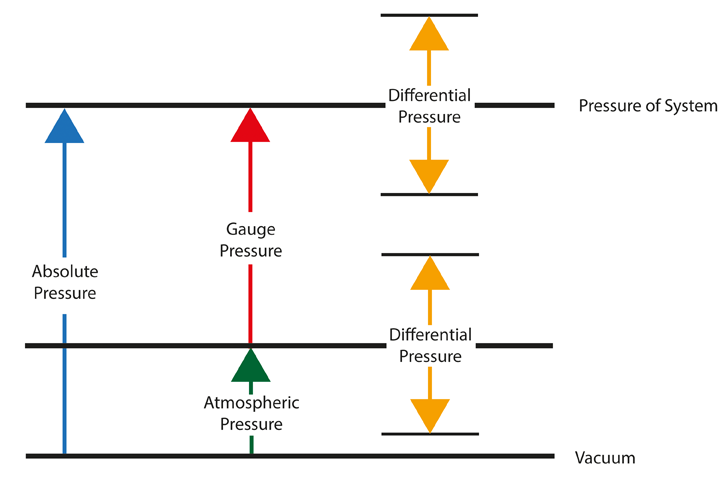

Absolute pressure uses a perfect vacuum or air-free space as its base reference of zero and uses a subscript of "abs" or “Pabs” which comes from the Latin term absolutus, which means independent or separated from. It is also used to refer to the perfect vacuum or "Absolute zero pressure".

A good example of absolute pressure would be barometric pressure. The pressure reference is the pressure of the atmosphere plus the gauge pressure of the media. A perfect vacuum has an absolute pressure reading of zero PSIA and the barometric average pressure at sea level is ~14.7 PSIA.

The formula for calculating absolute pressure is:

Pabs = Patm + Pg

The absolute pressure in liquids can not be negative as a liquid pushes rather than pulls. This means that the smallest absolute pressure is zero.

Some of the applications that use absolute pressure includes:

Gauge pressure (Pg) is the difference between atmospheric pressure (Pamb) and absolute pressure (Pabs) (Diagram 1). When gauge pressure is measured it must be noted that the pressure will change due to the barometric pressure from weather patterns, although this is not the case if the measuring point is exposed to ambient atmospheric pressure.

The formula for calculating gauge pressure is:

Pg = Pabs + Pamb

Some of the applications that Gauge pressure is used for are:

Differential pressure (DP or ∆P) is the difference in pressure between two points of pressure. To generate a reading one of the two pressures is either higher or lower than the other. If they are the same then no pressure reading will be generated.

Differential gauges are available in a number of versions including:

Differential bourdon tubes are essentially designed with two opposing bourdon tubes, each one having its own connection but operating a common pointer that shows the difference between the two pressures.

Two Melinex diaphragms are used as a barrier between the measuring diaphragm and the process medium, this allows for high static pressures to be applied.

Designed as a balanced bellows system, that converts the differential pressure into a rotary movement by way of mechanical linkages and a torsion tube assembly. The entire assembly is filled with liquid and produces a hydraulic self-lubricating measurement system. This allows for low differential pressure to be measured but at high static line pressures.

Budenberg Gauge offers a range of differential pressure gauges including:

Typical applications that require the use of differential pressure instruments are:

There are a number of units that can be used to measure pressure. The most commonly used are from the international system of units such as:.

A simple way to define the difference between absolute and gauge pressure measurement is that absolute pressure has absolute zero as its zero point. In comparison, gauge pressure uses atmospheric pressure as its zero point.

Atmospheric pressure is always variable as it changes with the height above sea level and climatic conditions at the time. An absolute pressure gauge is a sealed instrument so measures the actual pressure applied regardless of any change in atmospheric pressure, whereas a pressure gauge measures the pressure relative to the atmospheric pressure of the day.

Differential pressure measures the pressure drop across a system, i.e to monitor a filtration system within a pipeline, as the filter blocks the differential pressure upstream increases. The increase between upstream and downstream is the differential pressure.

While there is a need for absolute pressure instruments, the majority of pressure applications will work accurately with gauge pressure measurement or an alternative. By spending a little time to evaluate the correct pressure measurement, you will achieve a more accurate, economical and efficient way to measure the pressure in your pressure applications.

If you are unsure if your gauge has to measure absolute pressure or gauge pressure, please contact one of Budenberg Gauges' technical advisors.

Your details will not be shared with any organisation outside of Budenberg Gauge Co. Ltd. You may request to be removed from our database at any time.

To see our full privacy policy click here.

Budenberg Gauge Co Ltd is a premier manufacturer of instrumentation for a wide range of applications and markets. Quality and reliability have become the trademark of all Budenberg products and all our instruments are supplied with a standard warranty and carry a unique serial number for traceability purposes.